Introduction to Service ESC

The “service ESC” light is an indicator on the dashboard of many modern vehicles that alerts drivers of a potential issue with the electronic stability control (ESC) system.

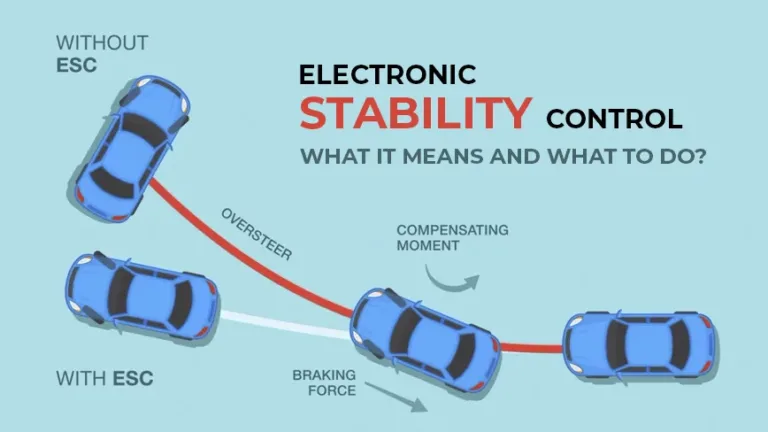

ESC is an important electronic system that helps improve vehicle stability and prevent loss of control.

ESC works by monitoring inputs from various sensors on the vehicle like wheel speed, steering angle, and yaw rate.

It processes this data to detect when the vehicle is beginning to lose traction or slide.

The ESC system can then automatically apply brakes to individual wheels and reduce engine power to help stabilize the vehicle.

ESC systems go by other names like electronic stability program (ESP), dynamic stability control (DTC), or vehicle stability control (VSC) depending on the auto manufacturer.

But they all serve the same essential purpose – to help keep the vehicle stable and prevent skidding or fishtailing, especially in slippery conditions or during sudden maneuvers.

The “service ESC” light indicates a fault has been detected with the ESC system. This could be due to a failed sensor, wiring issue, or a problem with the ESC computer module itself.

Ignoring this warning light is not recommended, as driving without a functional ESC system can significantly increase the chances of losing control.

Main Causes of Service ESC Light

The service ESC light indicates an issue with the electronic stability control system.

This is an important safety system that helps maintain vehicle stability and prevent skidding.

There are a few common causes for the service ESC light to come on:

Faulty Wheel Speed Sensor

The wheel speed sensors monitor how fast each wheel is turning.

If one of the sensors fails or gets damaged, it will provide incorrect data to the ESC module. This triggers the service ESC light.

Dirt, debris, and worn out sensors are common causes of wheel speed sensor failure.

Loose Steering Angle Sensor

The steering angle sensor detects how far the steering wheel is turned. It allows the ESC system to compare steering input to vehicle direction.

If the steering angle sensor is loose or disconnected, it can’t provide accurate data to the ESC module.

Issues with Yaw Rate Sensor

The yaw rate sensor measures sideways acceleration and rotation. It helps the ESC module determine if the vehicle is spinning or swerving.

Problems with the yaw rate sensor wiring, placement or calibration will trigger the service ESC light.

Faulty ESC Module

The electronic stability control module processes data from the wheel speed sensors, steering angle sensor and yaw rate sensor.

It then brakes individual wheels and reduces engine power to stabilize the vehicle. An internal failure in the ESC module itself will cause the service ESC warning light.

Symptoms of Service ESC Issues

The most common symptoms indicating an issue with ESC (Electronic Stability Control) include:

- ESC warning light staying on – This is the main indicator that there is a problem with the ESC system. Typically an amber or yellow “ESC” light will remain constantly illuminated if there is a fault detected. This light on the dashboard should turn off after a few seconds when starting the engine if the system is working normally.

- Reduced engine power – Faulty wheel speed sensors or other ESC components can trigger the engine control module to limit power as a precaution. Drivers may notice hesitations, lack of throttle response, or sudden power reductions.

- Traction or stability control problems – Malfunctions with the ESC system can disable traction control features like brake intervention at spinning wheels. Drivers may notice the vehicle has reduced ability to accelerate on slippery roads or recover from skids/slides.

- Warning messages about ESC – Many vehicles will display warning messages if the ESC system is experiencing technical problems. This may be a text alert about disabling ESC or detecting malfunctions. Read the owner’s manual for potential ESC-related warning codes and meanings.

In summary, the Check Engine light is the most common indicator of issues, but reduced power, loss of traction/stability assist, and warning messages can also occur.

Diagnosing and repairing the ESC system should be a priority to restore normal vehicle control and safety.

Diagnosing the Problem

When the service ESC light comes on, it means there is an issue with the electronic stability control system that needs diagnosis.

Here are the main steps to properly diagnose the problem:

- Use an OBD2 scanner to pull any diagnostic trouble codes related to the ESC system. This will give you a starting point on which components could be malfunctioning. Common codes include wheel speed sensor codes like C0035, yaw rate sensor codes like C0036, and steering angle sensor codes like C0037.

- Thoroughly inspect the wheel speed sensors located at each wheel. Look for damage, corrosions, bent sensors, etc. Unplug the sensors one at a time and check the resistance values per the factory spec. Values outside the spec indicate a bad sensor that needs replacement.

- Carefully check all wiring harnesses and connections related to the ESC system. Look for chafed, cut, pinched, or corroded wires. Make sure the connectors are fully seated and locking properly. Faulty wiring is a common cause of intermittent ESC problems.

- Test the yaw rate sensor and steering angle sensor by disconnecting them and ensuring the values change as expected when turning the steering wheel. If the values do not change or are erratic, the sensors may need to be replaced. Consult a factory service manual for the exact testing procedures.

Properly diagnosing the issue requires methodically checking each component of the ESC system, verifying fault codes, and testing sensors.

This will reveal the root cause and failed part causing the service ESC light to turn on.

Fixing Wheel Speed Sensors

The wheel speed sensors measure how fast each wheel is spinning and send that data to the ESC module.

If one or more sensors are malfunctioning, it can cause the Service ESC light to come on. Here are the steps to fix the wheel speed sensors:

Locate Bad Sensor

- Visually inspect wires and connectors for damage. Worn or frayed wires can cause intermittent signal problems.

- Use a scanner tool to view wheel speed data. Compare readings from all wheels when driving. If one reads zero or random values, that sensor is likely faulty.

- Check for trouble codes that identify a specific bad wheel speed sensor.

Unplug and Replace Sensor

- Remove wheel liner or inner fender panel to access sensor wiring.

- Unplug the electrical connector from bad sensor.

- Unbolt sensor from steering knuckle or brake assembly and remove.

- Install new OEM wheel speed sensor and tighten fasteners to spec.

Reconnect Electrical Harness

- Plug sensor connector back into wiring harness. Make sure it clicks into place securely.

- Refit any panels or wheel liners removed to access sensor.

Clear Codes with Scanner

- After new sensor is installed, reconnect battery if disconnected.

- Use a scanner tool to clear any ABS, ESC, or wheel speed sensor codes.

- Drive vehicle and verify sensor data looks normal and Service ESC light stays off.

Replacing the Steering Angle Sensor

The steering angle sensor detects the position and rate of steering wheel movement.

It sends this data to the ESC module to help stabilize the vehicle.

If diagnostics point to a faulty steering angle sensor, you’ll need to replace it. Here are the steps:

Remove the Old Sensor

- Locate the steering angle sensor, usually attached to the steering column near the firewall.

- Unplug the sensor’s electrical connector.

- Remove the fastener(s) securing the sensor to the column. These may be Torx bolts or other fasteners.

- Detach the sensor from its mounting location. Note the orientation for re-installation.

Install the New Sensor

- Position the new steering angle sensor in the same orientation as the old one.

- Reinstall any fasteners to secure it in place. Tighten them to the specified torque.

- Plug in the new sensor’s electrical connector. Make sure it clicks into place securely.

Reconnect and Reprogram

- Reconnect the vehicle battery if it was disconnected.

- Turn the ignition on. The ESC light should come on then go off.

- Using a scan tool, clear any diagnostic trouble codes (DTCs) related to the old sensor.

- Perform any necessary sensor calibration or reprogramming procedures per manufacturer specs. This “teaches” the ESC system the new sensor’s signals.

Following a successful installation, road test the vehicle. The ESC system should now operate normally without any dash lights or issues.

Schedule recurring sensor inspections to stay ahead of any future problems.

Fixing Yaw Rate Sensor

The yaw rate sensor measures the vehicle’s rotation around its vertical axis and sends this data to the ESC module.

If this sensor is faulty, it can trigger incorrect ESC activation and service lights. Replacing the yaw rate sensor involves:

- Locating the sensor, which is typically mounted behind or under the center console. Consult a repair manual for the exact location in your vehicle’s make and model.

- Unbolting and removing the old yaw rate sensor. There are usually two bolts securing it.

- Installing the new yaw rate sensor in the same orientation and securing it with the bolts. Torque bolts to specifications.

- Reconnecting the electrical harness to the new sensor. Make sure the connection is secure.

- Clearing any diagnostic trouble codes related to the yaw rate sensor so the service ESC light turns off. This can be done with a code scanner.

- Road testing the vehicle and making sure the service ESC light does not come back on. The ESC system should now have accurate data from the replaced sensor.

- Performing any necessary recalibrations of the ESC system as outlined in the vehicle repair manual. This completes the yaw rate sensor replacement.

Replacing ESC Module

The ESC module is the computer that controls the ESC system. If diagnostics indicate it is faulty, you will need to replace it.

Here are the steps to replace the ESC module:

- Locate the ESC module, usually mounted under the dashboard or in the engine bay. Consult a repair manual for the exact location in your vehicle.

- Unplug all the connectors going into the module. Make note of where each connector goes for re-assembly.

- Remove the bolts or screws securing the module in place.

- Install the new ESC module and secure it with the bolts/screws.

- Reconnect all the sensors, wiring harnesses, and connectors to the module. Double check that everything is securely plugged in.

- Turn the ignition on so the ESC module can power up. Do not start the engine.

- Many ESC modules require programming or configuration after replacement. This usually requires a professional scan tool. Follow the prompts to configure the new module.

- If programming is not available, you may need to perform a basic ESC initialization procedure outlined in the repair manual. This helps the ESC learn parameters for your vehicle.

- Clear any ESC-related diagnostic trouble codes. Turn the ignition off and back on to reset the ESC system.

- Test drive the vehicle and verify the service ESC light is no longer illuminated. The ESC system should now be fully operational.

Replacing the ESC module is crucial if it is faulty. Take care to properly reconnect all sensors and program the module if required. This will restore proper ESC system operation.

Verifying Repairs

After completing any repairs for the Service ESC system, it’s crucial to verify that the issue is fully resolved before returning the vehicle to the owner.

Follow these steps to confirm the repair:

- Clear all diagnostic trouble codes (DTCs) from the vehicle’s computer using a scan tool. Residual codes can cause confusion and inaccuracies.

- Complete a test drive of at least 10-15 minutes in a safe location. Drive on a variety of road surfaces and perform light steering maneuvers. The ESC system should not activate or light up the dash if operating normally.

- Upon returning from the test drive, inspect the instrument cluster to confirm the Service ESC warning light is no longer illuminated. If it remains on, further diagnosis and repair is still needed.

- Use a voltmeter or scan tool to check all sensors and electrical connections related to the ESC system. Compare the values to manufacturer specifications. Replace any questionable parts and retest.

- Focus sensor checks on the wheel speed sensors, steering angle sensor, and yaw rate sensor. Verify no wiring damage is present and the sensors are providing accurate data to the ESC module.

- When no codes are present, the ESC light is off, and all sensors read within spec, the repair can be considered complete. Test drive the vehicle once more to confirm normal operation before returning to the owner.

- Providing a test drive and verification process gives the repair an extra layer of diligence. It assures the owner that the fault has been properly repaired before they take the vehicle home.

Preventative Maintenance

Regular maintenance is key to preventing issues with your vehicle’s electronic stability control (ESC) system.

Here are some tips to keep your ESC system operating properly:

- Inspect sensors and wiring regularly – The ESC system relies on input from various sensors, so it’s important to periodically inspect them. Look for any loose connections, damaged wiring, or signs of wear. Key sensors include the wheel speed sensors, steering angle sensor, and yaw rate sensor. Replacing them proactively can prevent ESC problems.

- Check for ESC software/firmware updates – Like other electronic systems in your vehicle, the ESC module has software that gets periodically updated by the manufacturer. Connect your vehicle to a diagnostic scan tool and check if any new firmware is available. Keeping the software up-to-date improves performance and fixes bugs.

- Use quality components for repairs – Opt for OEM parts rather than cheap aftermarket components when repairs are needed. The sensors and ESC module are precision instruments and generic parts may seem like a bargain but don’t last as long. Investing in quality components reduces the likelihood of repeat repairs down the road.

Regular preventative maintenance checks will keep your vehicle’s ESC system running optimally, reducing the chances of the dreaded Service ESC warning light turning on unexpectedly.

Addressing small issues early also prevents more expensive repairs later on. Just a little time invested routinely goes a long way for ESC system longevity.