Your tires are the sole point of contact between your vehicle and the road, a critical, often overlooked, component directly impacting safety, performance, and fuel efficiency. They bear the weight of your entire vehicle, dissipate road forces, transmit steering and braking forces, and absorb road imperfections.

Yet, for many drivers, their condition is an afterthought until a problem arises. In 2023 alone, 646 people died on the road in tire-related crashes TireWise, NHTSA. This stark reality underscores why a proactive approach to tire care, leveraging an Ultimate Guide to Tire Maintenance and a thorough inspection checklist, is not just recommended – it’s essential for safe driving.

- The Critical Role of Tires in Vehicle Safety

- Preventative Maintenance for Peace of Mind and Your Wallet

- How Often Should You Inspect Your Tires?

- Your Step-by-Step Tire Inspection Checklist

- Understanding Irregular Tire Wear Patterns

- When to Seek Professional Tire Services

- Proactive Tire Care for Long-Term Safety and Performance

- Conclusion: Drive Confidently, Drive Safely

- FAQs

The Critical Role of Tires in Vehicle Safety

Tires are more than just round rubber objects; they are sophisticated engineering marvels designed to provide grip, stability, and control. Their condition directly influences your vehicle’s ability to stop, steer, and maintain traction, especially in challenging weather conditions.

Worn or improperly inflated tires can significantly increase braking distances, reduce steering responsiveness, and compromise stability, making them a silent hazard. A proper tire inspection is the first line of defense against these potential dangers.

Preventative Maintenance for Peace of Mind and Your Wallet

Regular tire inspection is a cornerstone of preventative vehicle maintenance. It allows you to identify potential issues before they escalate into dangerous situations or costly repairs. By dedicating a small amount of time to checking your tires, you can ensure your vehicle operates optimally, enhance your safety, and extend the lifespan of your tires.

This proactive approach translates directly into savings, from improved fuel economy to avoiding premature wear on other vehicle components like your brakes and suspension system. In fact, TyreSafe found that 75% of tyre defects were due to lack of maintenance in fatal incidents where car tires were a causal factor in 2024 TyreSafe.

How Often Should You Inspect Your Tires?

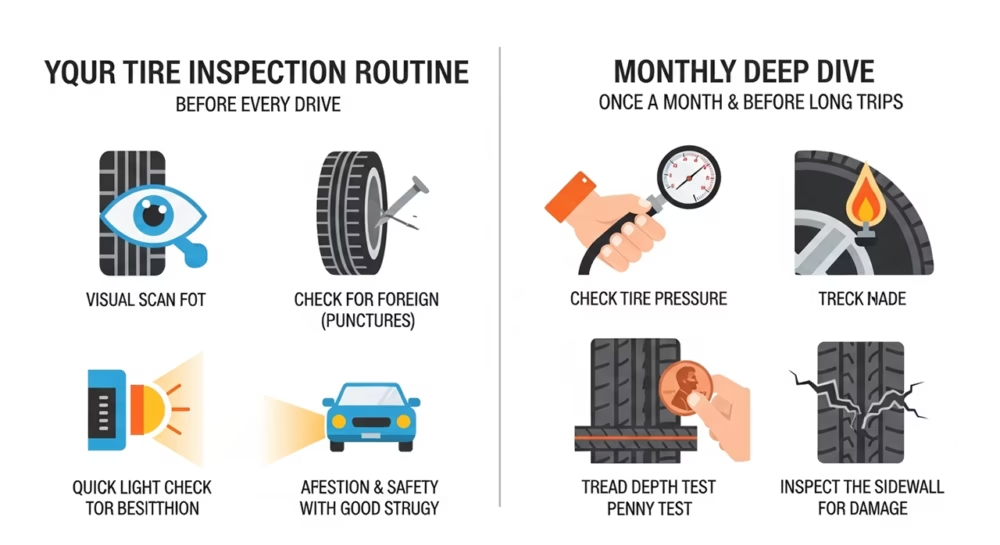

A regular tire inspection routine involves both quick daily glances and more thorough monthly checks to ensure safety.

Establishing a routine for tire inspection is key to maintaining optimal safety and performance. This doesn’t always require a deep dive; varying levels of inspection are beneficial.

The Quick Pre-Drive Check

A brief visual scan before each drive can catch obvious issues. This involves looking for any visible damage, foreign objects, or obvious signs of underinflation. While you’re at it, a quick glance at your vehicle’s lights ensures all are functioning correctly, contributing to overall road visibility and safety.

The Monthly Deep Dive

A more thorough inspection should be conducted at least once a month, and ideally before any long road trip. This monthly check allows for a comprehensive assessment of tire health, including pressure, tread depth, and sidewall integrity, preventing many common tire problems before they become serious.

Your Step-by-Step Tire Inspection Checklist

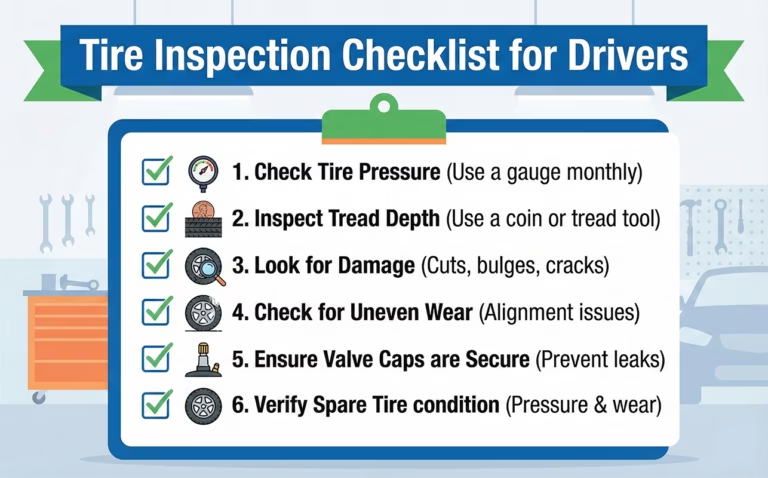

Performing a comprehensive tire inspection is straightforward and can be done with minimal tools. Following this checklist regularly will significantly enhance your tire safety.

Step 1: Check Tire Pressure (Air Pressure)

Proper tire pressure is paramount for safety, handling, and tire longevity. Underinflated tires can lead to poor handling, increased fuel consumption, and premature wear. Overinflated tires can result in a harsh ride, reduced traction, and an increased risk of blowouts.

- Find Your Vehicle’s Recommended PSI: The correct air pressure for your tires is not found on the tire sidewall itself. Instead, look for a sticker typically located on the driver’s side doorjamb, in the glove compartment, or on the fuel filler door. Consult your vehicle owner’s manual for precise recommendations. The number on the tire sidewall (maximum inflation pressure) is not the recommended operating pressure.

- Use a Reliable Tire Pressure Gauge: Invest in a quality tire pressure gauge. Digital gauges are generally more accurate and easier to read than their mechanical counterparts.

- Check When Tires Are Cold: For the most accurate reading, check your tire pressure when the tires have not been driven for at least three hours or have been driven less than a mile.

- Adjust as Needed: Add air if the pressure is low, or release air if it’s too high, until it matches the recommended PSI. Remember to check all four tires, plus the spare tire.

- Monitor TPMS: Many modern vehicles are equipped with Tire Pressure Monitoring Systems (TPMS). While these systems are valuable, they should not replace manual checks. The TPMS market is expected to grow significantly, indicating increased reliance on this technology Market Research Report.

Step 2: Measure Tread Depth

The tread depth of your tires is critical for grip, especially in wet or slippery conditions. Insufficient tread depth drastically increases stopping distances and the risk of hydroplaning.

- Legal Minimums: Most jurisdictions have a minimum legal tread depth, often around 2/32nds of an inch. However, safety experts recommend replacing tires before they reach this point.

- Use a Tread Depth Gauge: The most accurate way to measure tread depth is with a tread depth gauge. These are inexpensive and easy to use.

- The Penny Test (as a rough guide): If you don’t have a gauge, you can use a penny. Insert a penny into the deepest part of the tread groove with Lincoln’s head facing down. If you can see the top of Lincoln’s head, your tread depth is likely below 2/32nds of an inch and your tires need immediate replacement. For a safer margin, repeat this with a quarter; if the tread reaches the top of Washington’s head, you still have adequate tread.

- Check Multiple Points: Measure the tread depth in several locations across the tire (inner, outer, and center) to detect uneven tire wear.

Step 3: Inspect the Tire Sidewalls and Tread for Damage

A thorough visual inspection of the sidewall and tread surface is essential to identify any physical damage that could compromise the tire’s integrity.

- Sidewall: Examine the sidewall for cracks, cuts, bulges, blisters, or any signs of foreign objects embedded in the rubber. Damage to the sidewall is particularly dangerous as it is less reinforced than the tread area and can lead to a sudden blowout.

- Tread: Look for cuts, punctures, embedded nails, screws, or other debris in the tread area. Also, check for any unusual wear patterns (detailed in the next section).

- Cracks and Dry Rot: Aging rubber can develop cracks, often referred to as dry rot, especially if tires are exposed to sunlight and extreme temperatures. These cracks weaken the tire.

Step 4: Examine Lug Nuts for Tightness and Condition

While less frequent than tire-specific issues, checking lug nuts is a vital part of tire safety. Loose lug nuts can cause a wheel to detach from the vehicle, a catastrophic failure.

- Tightness: With the vehicle parked and the engine off, attempt to wiggle each wheel. Any significant looseness could indicate an issue with the lug nuts or studs. If you have a lug wrench, you can carefully check if the lug nuts are snug. Caution: Do not overtighten, as this can damage the studs. It’s best to have them torqued to the manufacturer’s specifications by a professional.

- Condition: Check for any signs of corrosion or damage on the lug nuts themselves.

Step 5: Determine Tire Age (The DOT Code)

Tires degrade over time, even if they appear to have sufficient tread. The rubber loses its flexibility and strength, increasing the risk of failure.

- Locate the DOT Code: The DOT code is a series of numbers and letters stamped on the sidewall of the tire.

- Identify the Manufacturing Date: The last four digits of the DOT code indicate the date of manufacture. The first two digits represent the week, and the last two represent the year. For example, “3221” means the tire was manufactured in the 32nd week of 2021.

- General Guideline: Most manufacturers recommend replacing tires that are 6 to 10 years old, regardless of tread depth, due to rubber degradation.

Step 6: Don’t Forget Your Spare Tire!

Your spare tire is a crucial safety net, but it’s often neglected. A flat tire can leave you stranded, and a useless spare offers no help.

- Check Pressure: Ensure your spare tire is inflated to the manufacturer’s recommended pressure. This is often higher than the standard tires.

- Inspect for Damage: Visually inspect the spare tire for cracks, bulges, or other damage.

- Confirm Availability: Make sure it’s securely mounted and accessible in your vehicle.

Understanding Irregular Tire Wear Patterns

Beyond the basic checklist, observing how your tires wear can provide valuable insights into the overall health of your vehicle and its systems, including the suspension, wheel alignment, and tire balance.

What Your Tires Are Telling You: Interpreting Wear

Different tire wear patterns are symptoms of underlying issues:

- Center Wear: Excessive wear in the center of the tread often indicates overinflation. The tire’s center is making the most contact with the road.

- Edge Wear (Both Edges): Wear on both the inner and outer edges of the tread typically signifies underinflation. The tire’s shoulders are bearing too much load.

- One-Sided Edge Wear: If one edge (either inner or outer) is significantly more worn than the other, it’s a strong indicator of improper wheel alignment. The wheels are not running parallel to each other or perpendicular to the road.

- Feathering: This wear pattern, where the tread blocks are worn smooth on one edge and have sharp edges on the other, often points to a wheel alignment issue.

- Cupping or Scalloping: These are rounded, scoop-like depressions on the tire tread. This pattern is frequently associated with unbalanced tires or worn suspension components. The tire is essentially bouncing or wobbling.

- Cracked Sidewalls: As mentioned, this is often a sign of age, exposure to UV rays, or chemical damage, indicating the tire is losing its structural integrity.

When to Seek Professional Tire Services

While regular DIY inspections are essential, some tire issues require the expertise and specialized equipment found at a professional tire shop.

Beyond DIY: When to Visit a Tire Shop

If your inspection reveals significant damage, such as deep cuts, sidewall bulges, or if you consistently notice issues with tire pressure or tire wear, it’s time to consult a professional. Ignoring these can lead to tire failure.

Wheel Alignment Services: Correcting Alignment Issues

If you notice uneven tire wear, your vehicle pulling to one side, or if you’ve recently hit a pothole or curb, your wheel alignment may be compromised. Misalignment causes tires to drag rather than roll freely, leading to rapid and uneven tire wear, poor handling, and increased fuel consumption. Professional alignment services ensure your wheels are set to the optimal angles, promoting even tire wear and optimal vehicle performance.

Tire Balancing: Preventing Vibrations and Uneven Wear

Over time, the weight distribution of a tire and wheel assembly can become uneven, especially after tire rotations or if a small weight falls off. This imbalance causes vibrations, which are often felt in the steering wheel or seat at certain speeds. If left unaddressed, tire balance issues can lead to a bumpy ride, premature tire wear, and unnecessary strain on your suspension components. Professional balancing distributes small weights around the wheel rim to counteract any imbalances.

Tire Rotation: Extending Tire Lifespan

Tire rotation is a preventative maintenance service that involves moving your tires from one position on the vehicle to another. This is done to promote even tire wear across all four tires, maximizing their lifespan and ensuring consistent performance. Front tires typically wear faster due to steering and braking forces, while rear tires may wear faster on rear-wheel-drive vehicles. Regular tire rotation (typically every 5,000 to 7,500 miles) helps equalize this wear.

Professional Tire Repair and Patch Services

Small punctures in the tread area of a tire can sometimes be repaired professionally using a patch or plug-patch combination. However, damage to the sidewall, large punctures, or severe wear typically necessitates tire replacement. Professionals can assess the damage and determine if a safe and reliable repair is possible.

Proactive Tire Care for Long-Term Safety and Performance

Making tire care a consistent part of your vehicle maintenance routine is the most effective way to ensure ongoing tire safety and optimal performance.

Incorporating Tire Checks into Your Car Maintenance Routine

Treat your tire inspection as you would checking your vehicle‘s oil or fluid levels. Schedule it monthly, and perform the quick pre-drive checks daily. Educate yourself on the signs of trouble, and don’t hesitate to seek professional help when needed. The global automotive tire market is projected to grow, indicating the increasing importance and sophistication of tire technology and maintenance Technavio.

The Link Between Tire Health and Overall Vehicle Safety

Remember that your tires are intrinsically linked to other critical vehicle systems. Healthy tires work in harmony with your brakes to provide adequate stopping power, with your suspension to ensure a stable ride, and with your steering system for precise control. Neglecting your tires can mask or exacerbate problems in these other areas, leading to a cascade of potential issues. Ensuring your tires are in top condition is fundamental to the overall safety and reliability of your vehicle.

Conclusion: Drive Confidently, Drive Safely

Your tires are your connection to the road, and their condition directly impacts your safety and the performance of your vehicle. By implementing a regular tire inspection checklist, you empower yourself to identify potential problems early, prolong the life of your tires, improve fuel efficiency, and most importantly, ensure a safer driving experience for yourself and others.

Recap of Key Inspection Points

Remember to regularly check your tire pressure, measure tread depth, inspect the sidewall and tread for damage, examine lug nuts, understand tire age, and never forget your spare tire. Pay close attention to any signs of irregular tire wear, as these can indicate underlying issues with your suspension or wheel alignment.

Your Role in Ensuring Road Safety

The statistics on tire-related fatalities and defects highlight a critical truth: many accidents are preventable. Your commitment to diligent tire maintenance is a significant contribution to overall road safety. It’s a simple yet profound way to protect yourself, your passengers, and everyone else sharing the road.

A Call to Action for Regular Tire Maintenance

Don’t wait for a problem to occur. Make tire inspection a non-negotiable part of your vehicle maintenance routine. A few minutes each month can prevent costly repairs, enhance your driving experience, and provide invaluable peace of mind. Drive with confidence, knowing that your tires are as safe and reliable as possible.

FAQs

What does a tire inspection include?

A comprehensive tire inspection is a systematic assessment of your tire’s overall health to ensure safety and longevity. It involves a combination of visual checks and physical measurements, specifically focusing on tire pressure, tread depth, and the structural integrity of the sidewalls. The inspection also extends to checking the condition of valve stems, ensuring lug nuts are secure, and verifying the readiness of your spare tire to prevent common issues from escalating into serious safety hazards.

What should be included in the inspection checklist?

Your checklist should follow a step-by-step approach starting with measuring the air pressure in all four tires plus the spare using a reliable gauge. Next, it should include measuring tread depth to ensure it meets legal and safety standards. The checklist must also contain a visual scan for sidewall damage like cuts, cracks, or bulges, a check for irregular wear patterns that might indicate alignment issues, and an inspection of the valve caps and stems for leaks or damage.

What are the common tire problems that a regular inspection can detect?

Regular inspections allow you to catch critical issues such as underinflation, which leads to poor handling and increased fuel consumption, or overinflation, which risks blowouts. It also helps detect insufficient tread depth that increases hydroplaning risks, and irregular wear patterns caused by misalignment or suspension problems. Furthermore, inspections can reveal physical damage like sidewall bulges, blisters, dry rot, or embedded foreign objects like nails before they cause a failure.

What tools and equipment are needed to properly inspect tires?

You can perform a professional-grade inspection with minimal tools. The most essential item is a quality tire pressure gauge, with digital models being recommended for their accuracy and readability. Additionally, a tread depth gauge is necessary for precise measurements of your remaining rubber; however, in a pinch, a penny can be used for the “Penny Test.” While not strictly equipment, having your vehicle’s owner’s manual handy is also crucial to verify the recommended PSI.

What safety precautions should drivers take when performing a tire inspection?

To ensure both safety and accuracy, you should perform inspections when the tires are “cold,” meaning the vehicle has been stationary for at least three hours or driven less than a mile. This prevents hot air from giving false pressure readings. Additionally, while Tire Pressure Monitoring Systems (TPMS) are valuable safety features, drivers are cautioned not to rely on them exclusively and to perform manual checks to ensure complete safety.

How do tread depth measurements factor into a tire inspection checklist?

Tread depth is a non-negotiable safety factor because it dictates your vehicle’s ability to grip the road, especially in wet conditions. The checklist requires verifying that tread depth is above the legal minimum (typically 2/32nds of an inch), though replacing tires before they reach this limit is often recommended for safety. Low tread depth drastically increases stopping distances, making this measurement a primary criteria for determining if a tire needs immediate replacement.

How often should drivers perform a tire inspection using a checklist?

Drivers should perform a full tire inspection using the checklist at least once a month. In addition to this monthly routine, it is highly recommended to conduct a thorough check before any long road trip to handle the increased stress on your vehicle. For optimal safety, the guide also suggests incorporating quick “pre-drive checks” into your daily routine to spot obvious deflation or damage.