The sweltering heat of summer or the biting cold of winter can quickly turn a comfortable drive into an ordeal if your car’s climate control system decides to malfunction.

In 2026, maintaining a functional air conditioning system is more than just a luxury; it’s a necessity for comfort, health, and even the resale value of your vehicle. As vehicle technologies evolve, so too do the complexities and costs associated with AC repair.

This comprehensive guide aims to demystify the world of car AC repair costs for 2025, covering everything from common issues and their causes to what you can expect to pay for diagnosis and fixes.

- Read out guide on DIY Car Maintenance for Beginners

We’ll navigate the intricate components of your AC system, the implications of changing refrigerant standards, and the factors that influence pricing, ensuring you’re well-equipped to handle any auto AC repair situation with confidence.

- Why a Functioning Car AC System is Essential

- What This 2025 Guide Will Cover

- How Your Car’s AC System Works: A Quick Primer

- Common Car AC Problems: Symptoms, Causes, and What They Mean for You

- Decoding the Diagnosis: What to Expect During an AC System Inspection

- Car AC Repair Costs: Average Prices for Common Problems & Fixes

- Factors That Significantly Influence Car AC Repair Costs

- Electric Vehicle (EV) AC Systems: A Different Ballgame

- Conclusion

- FAQs

Why a Functioning Car AC System is Essential

A well-functioning car air conditioning system provides more than just cool air. It significantly impacts occupant comfort, making long drives and daily commutes more bearable, especially during extreme weather. Beyond comfort, it plays a crucial role in air quality. By filtering and dehumidifying the air, it can reduce allergens, dust, and humidity, creating a healthier cabin environment.

For drivers prone to allergies or respiratory issues, a properly working AC is vital. Furthermore, a well-maintained AC system contributes to the overall health and longevity of your vehicle, preventing issues like mold growth within the ductwork and ensuring that critical components like the compressor operate efficiently. When it comes time to sell your car, a fully functional AC system is a significant selling point that can command a higher price.

What This 2025 Guide Will Cover

This guide is designed to be your definitive resource for understanding car AC repair costs in 2025. We will begin with a brief overview of how your AC system operates and its core components. A critical focus will be placed on the evolving landscape of refrigerant gases, specifically the transition from R-134a to the newer R1234YF standard and its cost implications.

We will then delve into the most common car AC problems, detailing their symptoms, potential causes, and what they signify for your vehicle’s air conditioning. Understanding the diagnostics process is crucial, so we will outline what to expect when technicians inspect your system and the associated diagnostic fees.

The heart of this guide will be a breakdown of average AC repair costs for common issues, including refrigerant recharge, refrigerant leak repairs, and component replacements like the compressor, condenser, and evaporator.

We will also explore the factors that significantly influence these costs, such as vehicle specifics, labor rates, and parts. Finally, we’ll touch upon the unique considerations for Electric Vehicle (EV) AC systems and offer advice on preventive maintenance and choosing the right repair shop.

How Your Car’s AC System Works: A Quick Primer

At its core, a car’s air conditioning system is a closed loop that utilizes a special fluid called refrigerant to absorb heat from the cabin and release it outside. This cycle involves several key components working in concert. The process begins when the compressor, driven by your engine, pressurizes the refrigerant gas, increasing its temperature.

This hot, high-pressure gas then flows to the condenser, typically located at the front of the vehicle, where it is cooled by outside air and transforms into a high-pressure liquid. The liquid refrigerant then passes through an expansion device (like an expansion valve or orifice tube), causing a rapid drop in pressure and temperature.

This cold, low-pressure liquid enters the evaporator, located inside the vehicle’s dashboard. As air from the cabin is blown across the evaporator‘s cold fins by the blower motor, heat is transferred from the air to the refrigerant, cooling the air before it’s circulated back into the cabin.

The refrigerant, now warmer and having absorbed heat, becomes a low-pressure gas and returns to the compressor to repeat the cycle. This continuous loop effectively transfers heat out of your car, providing the cooling effect you experience.

The Core Components of Your Vehicle’s Air Conditioning System

Understanding the primary parts of your AC system is fundamental to grasping why repairs can be complex and costly.

- Compressor: Often called the “heart” of the AC system, the compressor is responsible for circulating and pressurizing the refrigerant. Its failure is a major repair. The compressor clutch, a component that engages and disengages the compressor pulley, can also be a point of failure.

- Condenser: Situated in front of the radiator, the condenser dissipates heat from the refrigerant to the outside air, changing it from a gas to a liquid. Damage from road debris or corrosion can lead to its failure.

- Evaporator: Located inside the dashboard, the evaporator absorbs heat from the cabin air, thus cooling it. This component is often the most labor-intensive and expensive to replace due to its location behind the dashboard.

- Receiver/Drier or Accumulator: These components act as filters and reservoirs, removing moisture and debris from the refrigerant and storing it. Moisture is particularly damaging to the AC system.

- Expansion Valve or Orifice Tube: This critical part controls the flow of refrigerant into the evaporator, managing the pressure drop that initiates the cooling process.

- Hoses and Lines: A network of rubber and metal hoses connects the various components, carrying the refrigerant throughout the system. Leaks can occur here, especially at connection points or due to wear.

- Cabin Air Filter: While not directly involved in the cooling cycle, the filter cleans the air entering the cabin. A clogged filter restricts airflow and can contribute to musty smells, especially if mold begins to grow.

Understanding Refrigerant Gases: R-134a vs. R1234YF (2025 Standards)

The type of refrigerant used in your vehicle’s AC system significantly impacts repair procedures and costs. For many years, R-134a was the industry standard for automotive air conditioning. However, due to environmental regulations aimed at reducing greenhouse gas emissions, newer vehicles are increasingly equipped with R1234YF refrigerant.

R1234YF is considered a lower global warming potential (GWP) refrigerant compared to R-134a. While environmentally friendlier, R1234YF is also more expensive. The specialized equipment required for its safe handling, recovery, and recharging adds to the cost of service. Furthermore, the refrigerant leak detection and repair processes for R1234YF may also require specialized tools and training.

In 2025, many shops will be fully equipped to handle both types, but it’s crucial to know which refrigerant your car uses, as mixing them is impossible and can damage the AC system. If your vehicle uses R1234YF, expect refrigerant recharge services and repairs involving refrigerant leak detection to be pricier than those for older R-134a systems.

Common Car AC Problems: Symptoms, Causes, and What They Mean for You

Identifying the symptoms of a failing AC system is the first step toward a timely and less expensive AC repair. Ignoring early signs can lead to more severe damage and higher costs down the line.

“My AC is Blowing Hot Air or Not Cool Enough”

This is the most common complaint. The culprit is often a lack of refrigerant, which usually indicates a refrigerant leak. However, it can also be caused by a malfunctioning compressor, a clogged condenser (preventing proper heat dissipation), a faulty expansion valve, or even issues with the blend door actuator that controls airflow temperature. A simple refrigerant recharge might provide temporary relief, but if a leak isn’t found and fixed, the refrigerant will escape again, rendering the recharge futile and potentially leading to more extensive AC system damage.

“My Car AC is Making Loud Noises”

Unusual noises emanating from the AC system are a clear warning sign. A grinding or rattling sound often points to a failing bearing within the compressor. A loud clicking sound might indicate an issue with the compressor clutch not engaging properly or a pulley problem. Squealing noises could be related to a worn serpentine belt that drives the compressor. These noises suggest mechanical wear and tear, often requiring the replacement of the affected component, such as the compressor itself or the compressor clutch.

“There’s a Musty, Moldy, or Unpleasant Smell from My AC Vents”

A foul odor is typically caused by mold and mildew buildup within the evaporator core or the ventilation system. This often occurs when moisture is trapped, which can happen if the AC’s drain line is clogged, preventing condensation from escaping the vehicle. Another common cause is a dirty cabin filter. When the filter is saturated with debris and moisture, it becomes a breeding ground for bacteria and mold. Addressing this involves cleaning the system and often replacing the cabin filter. If left unchecked, mold spores can be circulated into the cabin, impacting air quality.

“Weak Airflow from the Vents”

If you notice that the air coming from your vents is significantly less forceful than usual, several issues could be at play. The most frequent cause is a clogged cabin filter, which restricts the volume of air that the blower motor can push through the system. Other possibilities include a failing blower motor resistor or the blower motor itself, or even blockages within the ductwork. While often a less expensive fix, a restricted airflow can put extra strain on other AC system components.

“Visible Water Leaks or Water Stains Under or Inside the Car”

A small amount of water dripping under your car when the AC is running is normal – it’s condensation from the evaporator. However, excessive water pooling or water stains inside the cabin can indicate a problem. This often points to a blocked AC drain tube, which causes water to back up and potentially leak into the car’s interior. In some cases, it could also signal a refrigerant leak that’s causing the evaporator to freeze over, and then melt, leading to excess water when it thaws. Cracked hoses can also be a source of external leaks.

Decoding the Diagnosis: What to Expect During an AC System Inspection

Before any AC repair can be effectively performed, a thorough diagnosis is essential. This process identifies the root cause of the problem, preventing unnecessary part replacements and ensuring the repair addresses the actual issue.

The Critical Role of Professional AC Diagnostics

Attempting to guess the problem with your AC system can be a costly mistake. AC diagnostics are performed by trained technicians who possess the knowledge and specialized tools to accurately pinpoint malfunctions. A professional diagnosis will not only identify faulty components but also detect subtle issues like small refrigerant leaks that might otherwise go unnoticed. This detailed assessment ensures that the subsequent AC repair is efficient and effective, saving you from repeated visits and potential further damage. It’s particularly crucial for complex problems involving pressure imbalances or hidden leaks.

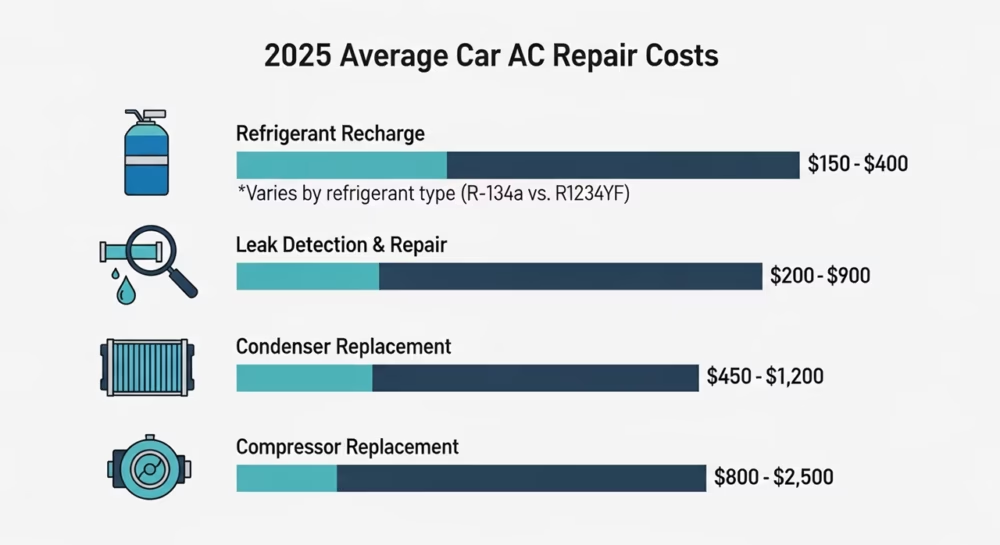

Cost estimates for common car AC repairs in 2025, from a simple recharge to a full compressor replacement.

Common Diagnostic Steps and Tools Technicians Use

When you bring your vehicle in for AC repair, technicians will typically follow a systematic diagnostic process:

- Visual Inspection: The technician will start by visually inspecting accessible components for obvious signs of damage, leaks (often using UV dye introduced into the system), or wear.

- Pressure Readings: Using manifold gauges connected to the high and low-pressure service ports, the technician will measure the refrigerant pressure. Deviations from specified ranges indicate issues with refrigerant levels, compressor performance, or blockages.

- Leak Detection: If low refrigerant is suspected, technicians use specialized tools like electronic “sniffers” or UV light with dye to pinpoint the exact location of any refrigerant leak.

- Electrical Testing: They will test electrical connections, fuses, relays, and switches that control the AC system, including the compressor clutch.

- Airflow Assessment: Checking the cabin filter, blower motor operation, and ductwork for restrictions.

- Temperature Readings: Measuring the air temperature coming from the vents to assess cooling performance.

Average Diagnostic Fees (2025)

The cost of AC diagnostics can vary based on the complexity of the problem and the shop’s labor rates. In 2025, expect to pay an average of $150 to $250 for a professional diagnostic service. Some shops might offer a diagnostic fee that is applied towards the cost of the subsequent repair if you proceed with the recommended work. It’s always a good practice to inquire about the diagnostic fee upfront and ask if it can be credited towards the repair.

Car AC Repair Costs: Average Prices for Common Problems & Fixes

Understanding the potential costs associated with various AC repair tasks is crucial for budgeting and making informed decisions. Prices can fluctuate based on the factors discussed later in this guide, but here are estimated averages for 2025.

Refrigerant Recharge Costs (and Why Just Recharging Isn’t Always the Fix)

A simple refrigerant recharge (adding refrigerant to the system) can range from $150 to $300. However, this is often a temporary solution. If your AC system is low on refrigerant, it’s almost certainly due to a refrigerant leak. Simply adding more refrigerant without finding and repairing the leak means the problem will reoccur, and you’ll continue to lose cooling efficiency and money. In some cases, a minor leak might be sealed during the recharge process using sealants, but professional detection and repair of the leak itself is generally recommended for a long-lasting fix.

Refrigerant Leak Repair Costs

Repairing a refrigerant leak involves several steps: diagnosing the leak’s location, repairing the damaged component or hose, and then evacuating the system and recharging it with the correct refrigerant. The cost for this can vary significantly depending on the leak’s severity and location. Expect prices to range from $200 to $700, potentially more if a major component like the compressor or condenser is the source of the leak and needs replacement. This includes the cost of leak detection and the refrigerant recharge.

AC Compressor Replacement Cost

The compressor is one of the most expensive components to replace. When a compressor fails, it often requires replacement of other system parts as well, such as the receiver/drier and possibly flushing the system to remove debris. The average cost for AC compressor replacement, including parts and labor, can range from $1,300 to $2,500 or more. For vehicles using R1234YF refrigerant, this cost could be higher due to specialized parts and handling requirements. The compressor clutch can sometimes be replaced separately if it’s the sole point of failure, costing less but still a significant repair.

Condenser Replacement Cost

The condenser is susceptible to damage from road debris and corrosion. If it fails, it needs to be replaced. The cost for replacing a condenser, including parts and labor, typically falls between $500 and $1,000. This price often includes the necessary evacuation and recharge of the refrigerant.

Evaporator Replacement Cost

Replacing the evaporator is often the most labor-intensive and therefore the most expensive AC repair. This is because it’s typically located deep within the dashboard, requiring extensive disassembly of the interior. The cost for replacing an evaporator can range from $1,500 to $3,000 or more, largely driven by the labor involved.

Receiver/Drier or Accumulator Replacement Cost

These components are often replaced as a preventative measure whenever the AC system has been opened, especially during compressor replacement, as they filter out moisture. The cost for replacing a receiver/drier or accumulator, including parts and labor, is generally between $300 and $500.

Other Common Auto AC Repair Costs

- Hose Repair / Replacement: A damaged AC hose can lead to refrigerant leaks. Repairing or replacing a single hose might cost between $200 and $400.

- Clutch / Compressor Clutch Replacement: If only the compressor clutch is faulty, replacing it can cost around $500 to $900, which is significantly less than a full compressor replacement.

- Cabin Filter Replacement: This is a relatively inexpensive maintenance item, costing approximately $30 to $80, but it’s crucial for airflow and preventing smells.

Factors That Significantly Influence Car AC Repair Costs

Several variables can cause the prices for AC repair to vary widely. Understanding these factors will help you better anticipate and budget for potential expenses.

Vehicle Make, Model, and Year

Luxury vehicles, European imports, and newer models often have higher AC repair costs. This is due to the complexity of their AC systems, the cost of specialized parts, and potentially more intricate designs that require more labor for access. Older vehicles might have readily available, less expensive parts, but system wear and tear can also lead to more frequent and costly repairs. The specific refrigerant type mandated for the vehicle year is also a major factor, with R1234YF systems being more expensive to service.

Labor Rates by Location and Shop Type

Labor rates are a significant component of any repair bill. Technicians in major metropolitan areas typically command higher hourly wages than those in rural areas, leading to increased overall repair costs. The type of repair facility also plays a role. Dealerships often have the highest labor rates, reflecting their specialized training, use of OEM parts, and overhead. Independent repair shops can offer more competitive pricing, while national chains might fall somewhere in between. Always factor in the prevailing labor rates in your specific region when estimating AC repair expenses.

OEM vs. Aftermarket Parts

When replacing components, you’ll often have a choice between Original Equipment Manufacturer (OEM) parts and aftermarket parts. OEM parts are made by or for the vehicle manufacturer and are typically more expensive, but they offer guaranteed compatibility and quality. Aftermarket parts are made by third-party manufacturers and can be significantly cheaper. While many aftermarket parts are of excellent quality, some may not meet OEM standards, potentially leading to shorter lifespans or performance issues. The choice between OEM and aftermarket can influence the total AC repair cost by hundreds or even thousands of dollars, especially for major components like the compressor.

Severity of the Problem and Scope of Work

The extent of the damage directly impacts the cost. A minor refrigerant leak that requires a simple patch and recharge will be far less expensive than a failed compressor that necessitates replacing multiple system components and flushing the entire AC system. If the evaporator is the issue, the extensive labor involved in accessing it will dramatically increase the bill. The scope of work also includes related tasks, such as replacing the receiver/drier when the system is opened or flushing the lines to remove contaminants, which adds to the overall expense.

Electric Vehicle (EV) AC Systems: A Different Ballgame

Electric vehicles present unique challenges and considerations for their air conditioning systems. Unlike traditional internal combustion engine vehicles, EV AC systems are often integrated with the vehicle’s thermal management system, which also cools the battery pack and other high-voltage components. This means the AC system in an EV might be more complex, utilizing higher voltage components and potentially different types of refrigerants and cooling loops.

Consequently, AC repair on EVs often requires specialized training for technicians, as well as unique diagnostic equipment and safety protocols for working with high-voltage systems. This specialization can translate to higher labor costs. While the fundamental principles of refrigeration apply, the integration with battery cooling and the use of electric compressors can lead to different failure modes and repair procedures.

For example, a failing electric compressor in an EV could be significantly more expensive to replace than its belt-driven counterpart in a gas-powered car. While specific cost data for EV AC repairs in 2025 is still emerging, owners should anticipate that specialized service will likely come with a premium compared to traditional vehicle AC repairs.

Conclusion

Navigating car AC repair costs in 2025 requires a clear understanding of your vehicle’s air conditioning system, common issues, and the factors influencing price. From the essential function of your AC system to the specific challenges posed by evolving refrigerant gases like R1234YF, knowledge is your best tool for avoiding unnecessary expenses and ensuring effective repairs. Recognizing symptoms such as blowing hot air, unusual noises, or musty smells is the first step toward proactive maintenance and timely AC repair.

The diagnostic process, performed by skilled technicians, is critical for accurate problem identification, preventing costly guesswork and ensuring repairs address the root cause, whether it’s a minor refrigerant leak or a major component failure like the compressor, condenser, or evaporator.

Be prepared for costs associated with refrigerant recharge, refrigerant leak detection and repair, and component replacements, which can range from a few hundred to several thousand dollars. Remember that factors like your vehicle’s make and model, regional labor rates, and the choice between OEM and aftermarket parts will significantly impact the final bill.

For EV owners, understanding the specialized nature of their AC systems and the associated costs is equally important. Ultimately, investing in regular AC service and timely AC repair is more economical in the long run, preserving comfort, air quality, and your vehicle’s value. By staying informed and choosing reputable repair shops, you can confidently manage your car air conditioning needs throughout 2025 and beyond.

FAQs

What are the typical costs for car AC repair?

The typical costs for car AC repair vary significantly depending on the severity of the issue and the parts required. For minor maintenance like a refrigerant recharge, prices generally range from $150 to $300. Moderate repairs, such as fixing a hose leak or replacing a receiver/drier, often cost between $200 and $500. However, major component failures result in much higher bills; replacing a condenser typically costs between $500 and $1,000, while replacing a compressor or evaporator can range from $1,300 to over $3,000 depending on the vehicle’s complexity.

What common problems cause car air conditioners to stop working?

The most common problem that causes an AC to stop working is a refrigerant leak, which can occur in the hoses, connection points, or the condenser. Because the system is a closed loop, low refrigerant means there is a leak that must be fixed. Other frequent issues include mechanical failure of the compressor (the heart of the system), physical damage to the condenser from road debris, or a clogged cabin air filter restricting airflow. Electrical issues, such as a failing compressor clutch or fuse, can also prevent the system from engaging.

What is the cost difference between refrigerant recharge and compressor replacement?

There is a massive cost disparity between a simple recharge and a compressor replacement. A refrigerant recharge is considered a basic maintenance task or temporary fix and typically costs between $150 and $300. In contrast, replacing the AC compressor is a major mechanical repair that involves expensive parts and significant labor, usually costing between $1,300 and $2,500. While a recharge basically refills the gas, a compressor replacement often requires flushing the entire system and replacing additional parts like the receiver/drier.

How much does it cost to repair an AC compressor What are some common reasons why the compressor fails in an AC unit ?

Replacing a faulty AC compressor is one of the most expensive AC repairs, with costs typically ranging from $1,300 to $2,500, or even higher for vehicles using the newer R1234YF refrigerant. Compressors usually fail due to internal wear and tear over time, but they can also break down prematurely if the system is contaminated with moisture or debris. Additionally, low refrigerant levels can cause the compressor to overheat due to a lack of lubrication. Sometimes, just the compressor clutch fails; if this part can be replaced separately, the cost is lower, typically between $500 and $900.

What is the average cost of AC repair and what factors affect the cost ?

Calculating a single “average” is difficult due to the wide range of potential issues, but minor repairs average around $300 to $500, while major system overhauls average between $1,000 and $2,000. The final cost is heavily affected by the specific component that failed—an easily accessible hose is cheap, while a dashboard-buried evaporator is expensive. Other major factors include the type of refrigerant your car uses (older R134a is cheaper than newer R1234YF) and whether you choose to use Original Equipment Manufacturer (OEM) parts or more affordable aftermarket alternatives.

What factors influence the price of car AC repairs?

Several key variables influence the price of AC repairs, starting with the vehicle’s make, model, and year. Luxury and European vehicles often have complex systems and require specialized parts that drive up costs. Labor rates are another significant factor; dealerships in metropolitan areas typically charge higher hourly rates than independent shops in rural locations. Furthermore, the type of refrigerant required plays a role, as newer cars (post-2015) often use R1234YF, which is significantly more expensive to service than the older standard refrigerants.

What are signs that indicate a car AC needs repair?

The most obvious sign that your AC needs repair is when the air blowing from the vents is warm or significantly less cold than usual. You might also notice weak airflow, which can indicate a clogged filter or failing blower motor. Audible warning signs include unusual rattling, grinding, or squealing noises when the AC is turned on, which often point to a failing compressor or clutch. Additionally, foul or musty odors coming from the vents can indicate mold growth in the evaporator or a drainage issue.

How can I troubleshoot my car’s AC not cooling properly?

To troubleshoot an AC system, you should first determine if the issue is airflow or temperature; if the air is cold but weak, check the cabin air filter. If the air is warm, listen for the “click” of the compressor clutch engaging under the hood when you turn the AC on. If the compressor doesn’t engage, the system likely has low pressure due to a leak. However, because the system relies on precise pressures and chemical refrigerants, the article recommends professional diagnosis to accurately identify if the root cause is a leak, a blockage, or an electrical failure.

Which car AC components are most prone to failure and costly to repair?

The AC compressor and condenser are among the most prone to failure. The compressor fails due to moving parts and high stress, and it is very costly ($1,300+) to replace. The condenser sits at the front of the car and frequently gets damaged by rocks and road debris, leading to leaks. However, the evaporator is arguably the most notorious regarding cost-to-repair; while it fails less often, it is buried deep inside the dashboard. Replacing it requires stripping the car’s interior, resulting in massive labor costs that can push the total bill over $1,500 to $3,000.

What are the best practices to extend the life of a car’s AC system?

To extend the lifespan of your AC system, you should run the air conditioner for at least 10 minutes once a week, even during the winter. This circulates the refrigerant and the oil it carries, keeping the compressor seals lubricated and preventing them from drying out and leaking. You should also replace the cabin air filter regularly to ensure the system doesn’t have to work harder than necessary to push air. Finally, addressing small leaks immediately is crucial, as a leak allows moisture to enter the system, which can cause internal corrosion and ruin expensive components like the compressor.