If you drive a modern car manufactured after 1980, you are almost certainly driving on Radial Tires. They are the global standard for safety, efficiency, and performance.

So, why are we still talking about Bias Ply Tires?

If you tow a boat, restore classic muscle cars, go rock crawling in a Jeep, or drag race on the weekends, the “Radial vs. Bias Ply” debate is not history—it is a daily decision.

Choosing the wrong construction for these specific applications can lead to poor handling, blown tires, or a ruined driving experience.

In this definitive guide, we are going to look under the rubber. We will strip away the tread to look at the internal carcass of the tire, explain the physics of how they handle load and heat, and help you decide exactly which technology belongs on your axle.

- Part 1: The Anatomy Lesson (What lies beneath?)

- Part 2: The Bias Ply Deep Div

- Part 3: The Radial Deep Dive

- Part 4: Head-to-Head Comparison

- Part 5: Specific Use Cases (Where the choice matters)

- Part 6: How to Identify Your Tires

- Part 7: The Safety Warning (Mixing Tires)

- Conclusion: Which is Better?

- Frequently Asked Questions (FAQ)

Part 1: The Anatomy Lesson (What lies beneath?)

To understand the difference, you have to understand that a tire is not just a rubber balloon. It is a high-tech composite structure made of fabric cords (plies) coated in rubber, and capped with steel belts.

The terms “Radial” and “Bias Ply” refer specifically to how these body plies are arranged inside the tire casing.

1. The Bias Ply Tire (The Old Guard)

Bias ply technology dates back to the very beginning of the automobile.

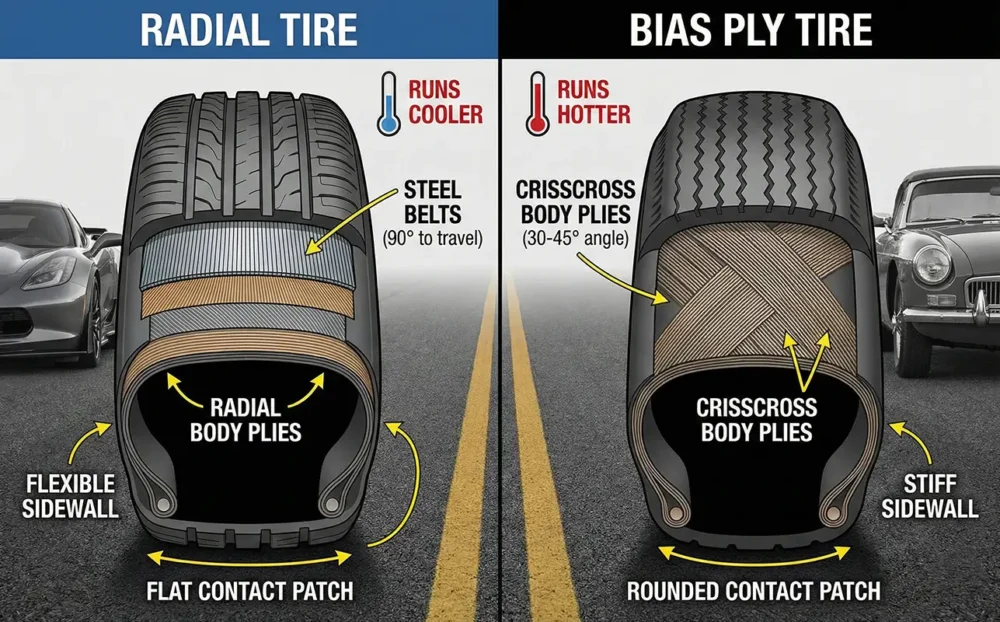

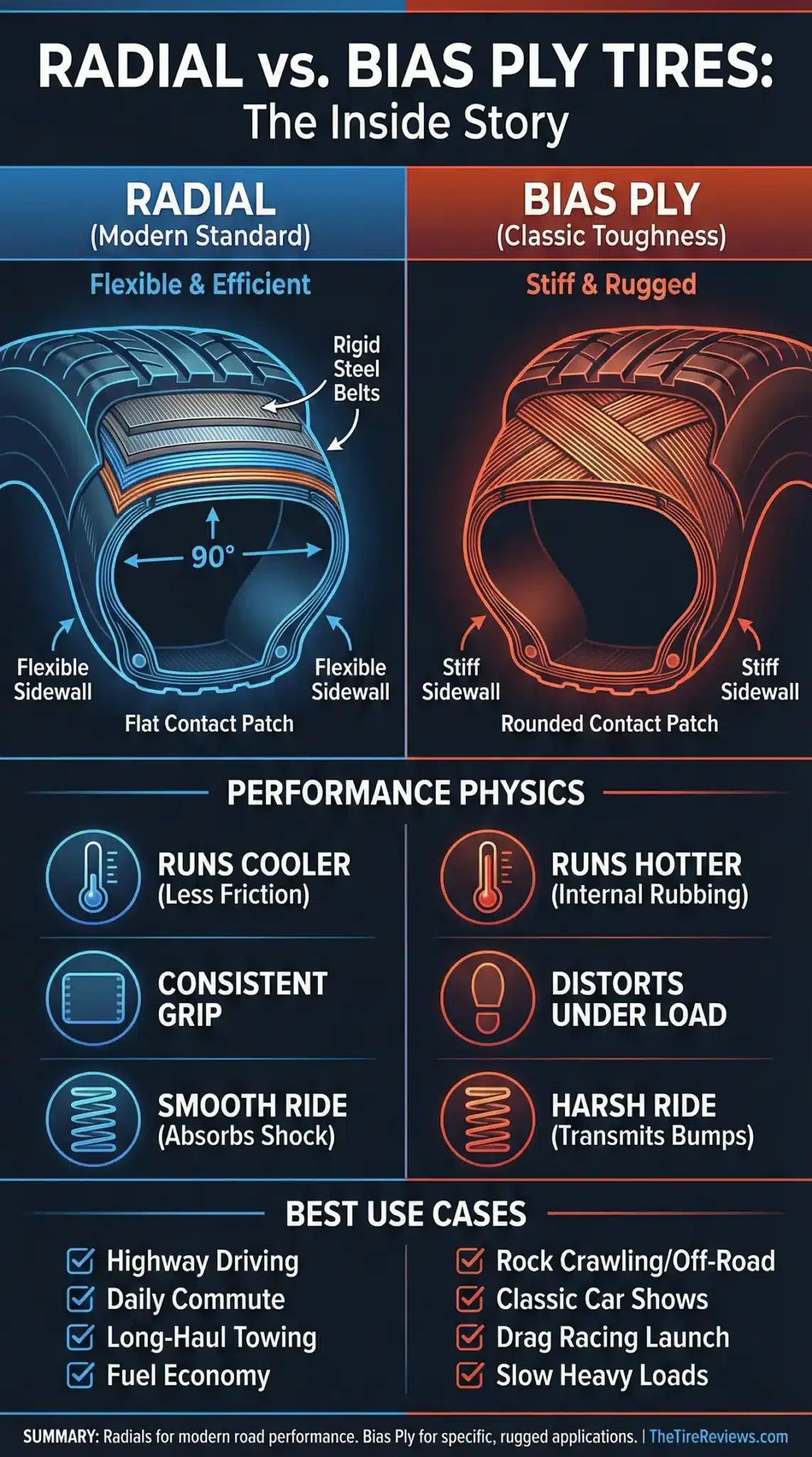

- Construction: The internal cords (made of nylon, polyester, or rayon) run diagonally across the tire from bead to bead. They crisscross each other in an “X” pattern, usually at an angle of 30 to 45 degrees.

- The Structure: Because the plies overlap, the sidewall and the tread are mechanically interdependent. They are one continuous unit. If the sidewall flexes, the tread flexes with it.

- The Analogy: Think of a bias ply tire like a tough hiking boot. It is stiff, thick, and the whole structure moves as one piece.

2. The Radial Tire (The Modern Standard)

Michelin introduced the Radial tire in 1946, and it revolutionized the industry.

- Construction: The body cords do not cross. They run perpendicular (90 degrees) to the direction of travel, straight across the tire from bead to bead, like the stripes on a zebra.

- The Structure: To give the tire stability, layers of steel belts are placed under the tread but over the radial casing. This creates a “two-part” system: the sidewall is flexible, but the tread is rigid.

- The Analogy: Think of a radial tire like a tank tread. The sidewalls act as the suspension (flexing and absorbing bumps), while the tread stays flat and glued to the floor.

Part 2: The Bias Ply Deep Div

Why do these still exist? If Radials are “better,” why hasn’t the Bias Ply gone the way of the carburetor? The answer lies in toughness and cost.

The Advantages of Bias Ply

- Sidewall Toughness: Because the crisscross plies run through the entire sidewall, a bias ply tire has vastly thicker, stronger sidewalls than a radial. This makes them resistant to punctures from rocks, curbs, or agricultural hazards.

- Load Stability (Static): In very specific heavy-load situations (like a crane or a forklift), the stiff sidewall prevents the tire from bulging or swaying.

- Cost: They are simpler to manufacture and require fewer raw materials, making them cheaper to buy.

The Disadvantages of Bias Ply

- Heat Buildup: This is the killer. As the tire rotates, the crisscrossing plies rub against each other (internal friction). This generates massive heat. Heat destroys tires. This makes bias ply tires unsuitable for high-speed highway driving.

- Flat Spotting: If you park a car with bias ply tires overnight, the tire cools down in the shape of the flat spot where it touched the ground. For the first 5 miles of driving the next morning, your car will thump and vibrate until the tires warm up and become round again.

- Wandering (Tramlining): Because the tread is not stabilized by steel belts, it tends to follow the ruts and grooves in the road. Driving a vintage car on bias plies requires constant steering correction.

Part 3: The Radial Deep Dive

Radial tires conquered the world because they solved the heat problem and the handling problem simultaneously.

The Advantages of Radial Tires

- Heat Dissipation: Because the internal cords don’t cross and rub, the tire runs much cooler. This allows for sustained high-speed driving (75+ mph) without the risk of a blowout.

- The “Flat” Footprint: Remember the tank tread analogy? Because the sidewall can flex independently of the tread, the contact patch stays flat against the road even when you turn a corner. This provides vastly superior grip.

- Rolling Resistance: Radials roll easier. This translates directly to better fuel economy (MPG) and less wear on the engine.

- Ride Comfort: The flexible sidewall acts as a secondary spring, absorbing small bumps and cracks in the pavement before they reach the suspension.

The Disadvantages of Radial Tires

- Vulnerable Sidewalls: To get that flexibility, the sidewalls are thin. If you scrape a sharp rock off-road, a radial is more likely to suffer a sidewall slice than a bias ply.

- Comparison Cost: They are more expensive to design and manufacture.

Part 4: Head-to-Head Comparison

Let’s break down the performance metrics that matter most to drivers.

1. Ride Quality

- Winner: Radial.

- Why: There is no contest here. Bias ply tires transmit every imperfection of the road into the chassis. Radials absorb shock. Switching a classic car from bias to radial often makes it feel like a completely different, modern vehicle.

2. Tread Life

- Winner: Radial.

- Why: Because the bias ply tire squirms and distorts as it rolls, the rubber scrubs against the pavement. Bias ply tires typically last 12,000 to 20,000 miles. A modern radial tire easily lasts 40,000 to 80,000 miles.

3. Load Carrying (Trailers)

- Winner: Tie (Depends on usage).

- Analysis: This is the most common debate in the RV and boating world.

- Bias Ply (ST): Great for short trips, farm use, or heavy loads carried at slow speeds. The stiff sidewall reduces trailer sway.

- Radial (ST): Essential for highway travel. If you are towing a camper across the country, you must use Radials. Bias ply tires will overheat and blow out on a 500-mile highway day.

4. Handling and Cornering

- Winner: Radial.

- Why: When a bias ply tire corners, the sidewall flexes, which pulls the tread up off the road. You lose traction. When a radial corners, the sidewall flexes, but the steel belts hold the tread flat.

Part 5: Specific Use Cases (Where the choice matters)

If you are putting tires on your Toyota Camry, buy Radials. End of discussion. But for the following groups, the choice is nuanced.

Scenario A: The Classic Car Restoration

You have a 1967 Ford Mustang. You want to win a “Concours” car show trophy.

- The Purist Choice: You need Bias Ply tires. To score 100 points at a serious show, the car must look exactly as it did on the showroom floor. Radials look “wrong” on classic cars because the sidewall bulges differently and the tread pattern is too modern.

- The Driver’s Choice: You need Radials. If you plan to actually drive the car to the show (rather than trailer it), bias ply tires are terrifying by modern standards. They wander, they have poor braking traction, and they flat-spot.

- The Compromise: Companies like Coker Tire now manufacture “Radial-Look Bias” tires. These are internally built as radials (for safety and ride) but molded to look exactly like vintage bias ply tires on the outside.

Scenario B: Off-Roading and Rock Crawling

You are building a dedicated trail rig (Jeep or Bronco).

- The Radial: Best for “Overlanding”—driving 200 miles on the highway to get to the trail, doing the trail, and driving home.

- The Bias Ply: The king of extreme rock crawling (e.g., Super Swampers).

- Why? When you “air down” a tire to 8 PSI for grip, a radial sidewall bulges excessively and becomes weak. A bias ply sidewall is so stiff it essentially supports itself even at low pressure, and it wraps around rocks like a claw without puncturing.

Scenario C: Drag Racing

You are at the drag strip on a Friday night.

- The Choice: Bias Ply Slicks.

- Why? You want the “Wrinkle Wall” effect. When a 1,000-horsepower car launches, a stiff radial tire would just spin. A bias ply drag slick is designed to buckle and twist (wrinkle) at the sidewall. This twisting action stores energy like a spring and softens the shock to the drivetrain, allowing the car to hook up and launch violently without breaking the axles.

Scenario D: Trailer Tires (ST)

- The Guideline:

- Utility Trailer (Dump run/Mulch): Bias Ply is fine. They are cheaper and handle the abuse of curbs and overload well.

- Travel Trailer/Boat (Highway): Radial. Heat is the #1 cause of trailer blowouts. Radials run cooler and track straighter, reducing the white-knuckle sway often felt when towing.

Part 6: How to Identify Your Tires

You can tell the difference just by looking at the sidewall code.

Radial: Look for the letter “R” in the size.

- Example: ST205/75R15

- The “R” stands for Radial.

Bias Ply: Look for a dash (-), a “D” (Diagonal), or a “B” (Bias) in the size.

- Example: ST205/75D15 or 7.00-15

- The lack of an “R” indicates bias construction.

Visual Check:

- Radials usually have a “bulge” where the tire meets the road, even when properly inflated.

- Bias ply tires stand very upright and straight, with almost no sidewall bulge.

Part 7: The Safety Warning (Mixing Tires)

This is the most critical section of this article.

NEVER mix Radial and Bias Ply tires on the same vehicle.

Doing so is dangerous and can cause uncontrollable instability.

- The Physics: Radials and Bias tires have completely different “slip angles” (how much the tire twists before it loses grip).

- The Scenario: If you put Radials on the rear and Bias on the front, the rear of the car will grip while the front wanders. If you do the reverse (Bias rear, Radial front), the rear end will swing out (oversteer) in a turn, likely causing a spin-out.

Trailer Exception: While you should never mix them on the same axle, you technically can have radials on the tow vehicle and bias ply on the trailer. However, for the sake of sway control, it is highly recommended to match the technology.

Conclusion: Which is Better?

The word “better” depends entirely on your mission.

Choose Radial Tires If:

- You drive on the highway.

- You value ride comfort and silence.

- You want your tires to last more than 20,000 miles.

- You are towing a camper, boat, or livestock trailer long distances.

- You want the best possible fuel economy.

Choose Bias Ply Tires If:

- You are restoring a classic car for show points only (trailer queen).

- You are building an extreme rock crawler that sees almost no pavement.

- You are drag racing and need high-launch traction.

- You have a farm trailer or hay wagon that never exceeds 40 mph and carries heavy loads over stumps and rocks.

- You are on an extremely tight budget for a utility trailer.

For 99% of drivers, as recommended in our ultimate tire buying guide, the Radial tire is the crowning achievement of automotive rubber engineering. It is safer, lasts longer, and drives better. But for that 1% of enthusiasts keeping history alive or pushing the limits of off-road traction, the Bias Ply remains a legendary tool in the box.

Frequently Asked Questions (FAQ)

Do bias ply tires hold air better than radials?

Generally, no. Air retention depends on the inner liner quality, not the ply construction. However, because bias ply sidewalls are stiffer, they may not look flat even when they are dangerously low on air, whereas a radial looks flat immediately. Always use a gauge.

Why do bias ply tires look skinnier?

Vintage bias ply tires typically had a higher “Aspect Ratio” (e.g., 80 or 90 series). They were tall and narrow to cut through snow and mud. Modern radials are wider to maximize the contact patch for asphalt grip.

Can I use radial tubes in bias ply tires?

No. Radial tubes are designed to handle the specific flexing of a radial sidewall. Putting a radial tube in a bias tire (or vice versa) can cause friction between the tube and the tire carcass, leading to a blowout. Always match the tube type to the tire construction.

What is a “Belted Bias” tire?

This was a transitional technology in the late 60s and early 70s. It used a bias ply body (diagonal cords) but added fiberglass belts under the tread for stability. It was better than a standard bias ply but inferior to a radial. They are rare today but available for specific muscle car restorations.

Why do my trailer tires blow out so often?

The most common cause is using Bias Ply tires at speeds exceeding their tire speed rating while Under-Inflated. Bias ply tires build heat rapidly. If you drive 75 mph on a hot day with a heavy load, the internal temperature of a bias tire can exceed its structural limit. Switch to Radials for highway towing.