Walk into any tire shop or browse an online configurator, and you will be bombarded with terms: “Alloy,” “Aluminum,” “Steel,” “Mag,” “Forged,” and “Cast.”

For the average driver, this terminology can be incredibly confusing. Is an “Alloy” wheel better than an “Aluminum” wheel? Are they the same thing? Why does one set cost $400 and another look-alike set cost $4,000?

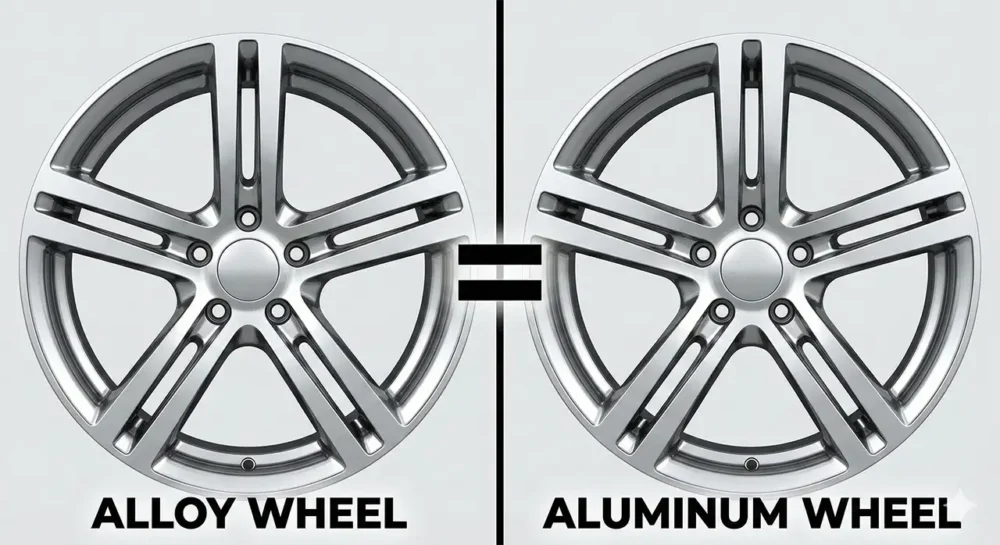

Here is the short answer to the most common question: In the modern automotive world, “Alloy Wheels” and “Aluminum Wheels” are almost always the exact same thing.

However, the story doesn’t end there. While the terms are used interchangeably, there are massive differences in how those wheels are made, the specific metal blends used, and how they perform on your vehicle.

In this comprehensive guide, we are going to deconstruct the metallurgy, the manufacturing processes, and the performance physics of wheels.

We will clarify the confusing terminology, compare them against the old-school “Steelies,” and help you decide exactly which type of metal should be rolling under your car.

- Part 1: Clearing the Confusion (The Terminology)

- Part 2: The Main Event – Alloy (Aluminum) vs. Steel

- Part 3: The “Real” Difference – Manufacturing Methods

- Part 4: The Outliers – Magnesium and Chrome

- Part 5: Which Wheel is Right for You?

- Part 6: Maintenance and Repair Differences

- Part 7: The Future – Carbon Fiber

- Conclusion

Part 1: Clearing the Confusion (The Terminology)

To understand the difference, we first have to pretend we are in a chemistry class.

What is “Aluminum”?

Aluminum is an element on the periodic table (Symbol: Al). It is a lightweight, silver-white metal.+1

- Properties: It is roughly one-third the weight of steel, highly resistant to corrosion, and conducts heat very well.

- The Catch: Pure aluminum is actually very soft. If you made a car wheel out of 100% pure aluminum, it would deform the first time you hit a speed bump. It simply lacks the structural rigidity to support a 4,000-lb vehicle.

What is an “Alloy”?

An “alloy” is not a specific metal; it is a mixture. An alloy is formed by taking a base metal (like aluminum or iron) and melting it together with other elements to improve its properties—making it stronger, harder, or lighter.+1

The “Alloy Wheel” in Marketing

When car manufacturers say “Alloy Wheels,” they are using a shorthand marketing term.

- Scientific Reality: Almost every metal wheel is an alloy. Even basic steel wheels are an alloy of Iron and Carbon.

- Automotive Reality: In car speak, “Alloy Wheel” specifically refers to Aluminum Alloy. This is a blend of roughly 90-95% Aluminum, mixed with Silicon, Magnesium, and other trace metals to give it strength.

The Verdict: When you see “Alloy” vs. “Aluminum” in a catalog, they are referring to the same product class. The real comparison you need to make is between Aluminum Alloy and Steel, or between the different types of Aluminum Alloys (Cast vs. Forged).

Part 2: The Main Event – Alloy (Aluminum) vs. Steel

While the user prompt asks about “Alloy vs. Aluminum,” the practical decision most drivers face is “Alloy vs. Steel.” Understanding this contrast highlights why aluminum alloys became the industry standard.

1. The Weight Factor (Unsprung Mass)

This is the single biggest advantage of aluminum alloy wheels.

- Steel: Heavy and dense. A standard 16-inch steel wheel might weigh 25-30 lbs.

- Aluminum Alloy: Light and rigid. That same size alloy wheel might weigh 18-20 lbs.

Why does this matter? It comes down to Unsprung Weight. This is the weight of everything below the suspension springs (wheels, tires, brakes).

- Performance: Reducing unsprung weight helps the suspension react faster to bumps. The wheel can move up and down more quickly, keeping the tire in contact with the road.

- Acceleration: A lighter wheel has less “rotational mass.” It takes less energy for the engine to spin it up, leading to faster acceleration and slightly better fuel economy.

2. Strength and Durability (Bend vs. Crack)

This is where the debate gets interesting. Lighter isn’t always “stronger” in every sense.

- Steel (The Bender): Steel is malleable. If you hit a massive pothole with a steel wheel, it will likely bend. The tire might hold air, and you can often hammer the rim back into shape with a mallet.

- Alloy (The Cracker): Aluminum alloy is more brittle. It is incredibly strong up to a point, but when it fails, it tends to crack or shatter. Once an alloy wheel is cracked, it usually cannot be safely repaired; it must be replaced.

3. Heat Dissipation

Your brakes work by friction, which generates massive heat. If that heat isn’t dissipated, your brake fluid can boil, leading to “brake fade” (where the pedal goes to the floor, and you don’t stop).

- Aluminum Alloy: Aluminum is an excellent conductor of heat. The wheel acts as a massive heat sink, pulling thermal energy away from the brake rotors and releasing it into the air. The open-spoke designs of alloy wheels also allow for better airflow.+1

- Steel: Steel is a poor conductor and retains heat. Steel wheels also typically have fewer openings (often just small circular holes), which traps heat inside the brake assembly.

Part 3: The “Real” Difference – Manufacturing Methods

If “Alloy” and “Aluminum” are the same material, why do some cost $150 and others $1,500?

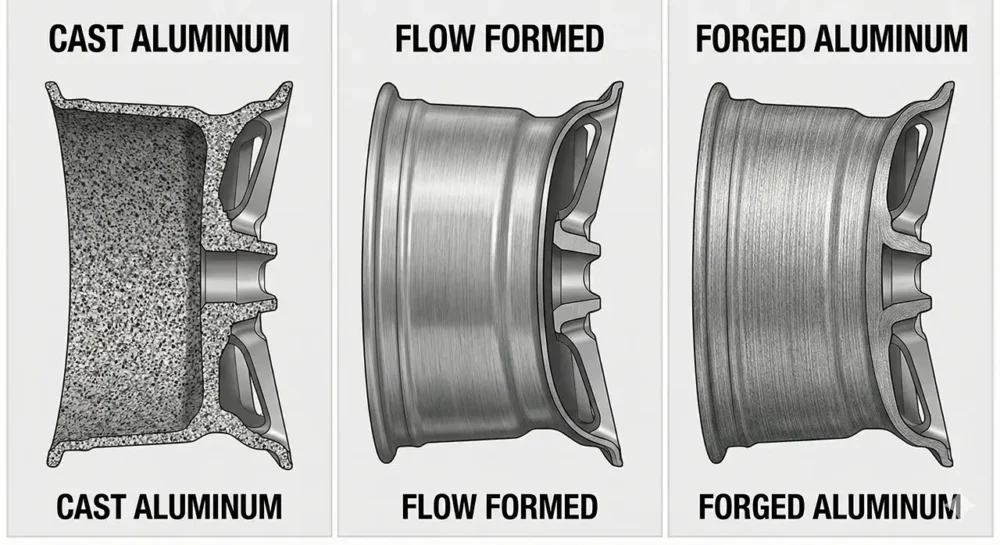

The difference lies in how the aluminum is formed. This is the most critical section for anyone looking to buy aftermarket wheels.

1. Cast Aluminum (The Standard)

90% of the alloy wheels on the road are Cast.

- The Process: Molten aluminum alloy is poured (or injected) into a mold. It cools, hardens, and is then machined into the final shape.

- Pros: Cheap and easy to mass-produce. Limitless styling options.

- Cons: The grain structure of the metal is random and porous. To make it strong enough, engineers have to use more metal, making cast wheels heavier than other aluminum types.

- Gravity Casting: Molten metal is poured in. Cheapest, heaviest.

- Low-Pressure Casting: Metal is pumped in quickly. Denser, stronger than gravity cast.

2. Flow Formed / Spun Forged (The Hybrid)

This is the “Goldilocks” zone—the best balance of price and performance. You will see brands like Konig, Enkei, and TSW using this method.

- The Process: The face of the wheel is cast, but the barrel (the part the tire sits on) is heated and spun on a machine. Rollers press down on the barrel, stretching the aluminum out like pottery on a wheel.

- The Result: This stretching aligns the grain structure of the aluminum, making the barrel much stronger and thinner. A flow-formed wheel is significantly lighter than a cast wheel but much cheaper than a forged one.

3. Fully Forged (The Ultimate)

This is what you find on Ferraris, F1 cars, and high-end aftermarket builds (like HRE or Vossen).

- The Process: The wheel starts as a solid block (billet) of high-grade 6061 Aluminum. A massive machine presses this block with thousands of tons of pressure, crushing the metal into the wheel shape.

- The Result: The immense pressure eliminates all porosity and creates a tightly aligned grain structure.

- Pros: Ideally strong and incredibly light. You can use very thin spokes that would snap if they were cast.

- Cons: Eye-wateringly expensive ($1,000+ per wheel).

4. Billet (The Custom Choice)

Billet wheels are cut from a solid block of aluminum using a CNC machine.

- Difference from Forged: Billet wheels are cut, not crushed. They retain the original grain structure of the block. They are strong and allow for crazy custom designs (common in the hot rod scene), but they aren’t quite as structurally optimized as a forged wheel.

Part 4: The Outliers – Magnesium and Chrome

We can’t discuss “Alloy vs. Aluminum” without mentioning the other terms that get thrown around.

Magnesium Wheels (“Mags”)

In the 1960s, “Mag Wheels” was the slang for any cool aftermarket wheel. Real racing wheels back then were made of Magnesium Alloy.

- The Good: Magnesium is even lighter than aluminum and has a higher strength-to-weight ratio.

- The Bad: Magnesium is highly susceptible to corrosion and can actually catch fire in extreme accidents (magnesium fires are difficult to extinguish).

- Modern Reality: True magnesium wheels are rare today, mostly reserved for Formula 1 and exotic hypercars. Most people saying “Mags” just mean “Aluminum Alloys.”

Chrome Wheels

“Chrome” is not a wheel material; it is a finish.

- A chrome wheel is almost always an Aluminum Alloy (or sometimes Steel) wheel that has been coated in layers of copper, nickel, and chromium plating.

- Note: Chrome adds weight. It can also flake off if the aluminum underneath corrodes (a process called pitting), causing tire leaks at the bead.

Part 5: Which Wheel is Right for You?

Now that we have decoded the dictionary, let’s apply this to your driving style.

Scenario A: The Daily Commuter / Winter Warrior

- Recommendation: OEM Cast Aluminum or Steel Wheels (for Winter).

- Why: For daily driving, standard factory alloy wheels are perfect. They look good and offer decent performance.

- Winter Tip: If you live in the Rust Belt, buy a cheap set of Steel Wheels for your snow tires. Steel doesn’t suffer from cosmetic corrosion like aluminum does. If you slide into a curb on ice, a $60 steel rim is cheap to replace compared to a $400 alloy.

Scenario B: The Track Day Enthusiast

- Recommendation: Flow Formed or Forged Aluminum.

- Why: On a track, weight is the enemy. Moving from a 25lb cast wheel to an 18lb flow-formed wheel will noticeably improve your braking distances and turn-in response. You also need the heat dissipation capabilities of aluminum to keep your brakes from fading after 5 laps.

Scenario C: The Off-Roader

- Recommendation: Small Diameter Cast Aluminum or Beadlock Capable.

- Why: Off-roaders want more tire sidewall, so they often choose smaller wheels (17-inch). While steel wheels are durable, they are heavy. Modern off-road “Alloy” wheels are built extra thick to handle rock crawling without cracking.

Part 6: Maintenance and Repair Differences

The material dictates how you care for the wheel.

Polishing and Cleaning

- Aluminum/Alloy: Aluminum oxidizes. If you have “bare” polished aluminum wheels, you must polish them regularly, or they will turn cloudy and white. Most modern alloys are “Clear Coated” (painted), so you treat them like the body of the car—soap and water. Warning: Acid-based wheel cleaners can strip the clear coat or stain bare aluminum. Always use pH-neutral cleaners.+1

- Steel: Usually painted black. Very low maintenance. If they rust, you can sand them down and spray paint them with a $5 can of Rust-Oleum.

Repairing Damage

- Curb Rash: Both can be fixed. Alloy wheels can be sanded and repainted or CNC-lathed (diamond cut) to look new.

- Bends: Steel wheels can often be hammered straight. Alloy wheels can be straightened by a professional using heat and hydraulic presses, but it weakens the metal. Many shops will refuse to fix a severely bent alloy wheel for liability reasons.

- Cracks: As mentioned, cracked alloy wheels should be scrapped. Welding an alloy wheel is risky and usually not recommended for street use.

Part 7: The Future – Carbon Fiber

Are we moving past metal entirely? High-end manufacturers (Ford with the Shelby GT500, Koenigsegg) are now offering Carbon Fiber Wheels.

- The Physics: Carbon fiber is woven resin. It is roughly half the weight of an aluminum wheel.

- The Performance: The reduction in rotating mass is shocking. Drivers report that the car feels like it has gained 50 horsepower simply because the engine doesn’t have to spin heavy metal flywheels at each corner.

- The Downside: They are brittle in specific impact scenarios and cost upwards of $15,000 a set. For now, Aluminum Alloy remains the king.

Conclusion

So, to answer the original question: There is no difference between “Alloy” and “Aluminum” wheels in 99% of consumer contexts. They are two names for the same modern standard—a wheel made from an aluminum blend designed to be light, attractive, and strong.

The real choice lies in how that aluminum wheel is made.

- Choose Cast Alloy for affordability and style.

- Choose Flow Formed Alloy for a performance upgrade on a budget.

- Choose Forged Alloy if you demand the absolute best in strength and weight reduction.

- And don’t rule out Steel if you need a sacrificial set of wheels for brutal winter conditions.

Your wheels are more than just jewelry for your car; they are structural components that keep you safe. Understanding the metal beneath the paint ensures you aren’t just buying a look—you’re buying the right tool for the road.

Glossary of Terms

- Unsprung Weight: Mass of suspension components not supported by the springs. Lower is better.

- Billet: A solid block of metal from which a part is cut/machined.

- Bolt Pattern: The arrangement of lug holes (e.g., 5×114.3). Aluminum wheels are drilled for specific patterns; steel wheels are essentially stamped.

- Hub Centric: A wheel designed so the center bore fits perfectly on the vehicle’s hub, carrying the load. Most factory alloy wheels are hub centric.

- Offset (ET): The distance from the hub mounting surface to the centerline of the wheel. Crucial for fitment.